Hammermill Models

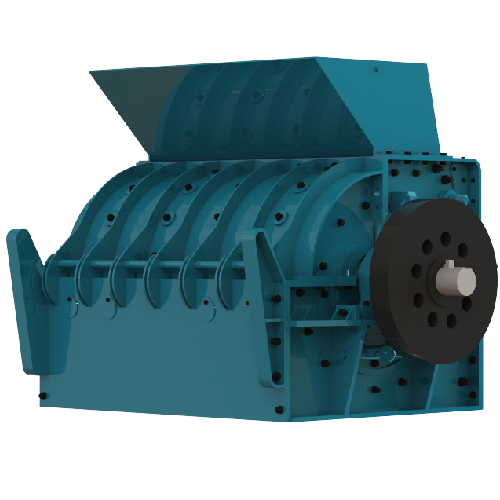

There are five variations of the Lanway Hammermill. They are the Lanway No1, No2, No3, No4 and No5 respectively. The first being the smallest model with the least output and the last being the largest model with the highest output.

Service & Support

Our personnel have the expertise and in-depth knowledge of your Lanway Hammermill. They are able to service, refurbish and fit replacement spare parts to your machine or supply you with spare parts which are available from stock.

Contact Us

If you would like more information on the various Lanway Hammermills, service, support and wear parts or any other information that has not been provided on this website then please contact a member of our sales team on + 44 (0)1352 732284.

Proven Performance. Exceptional Reliability.

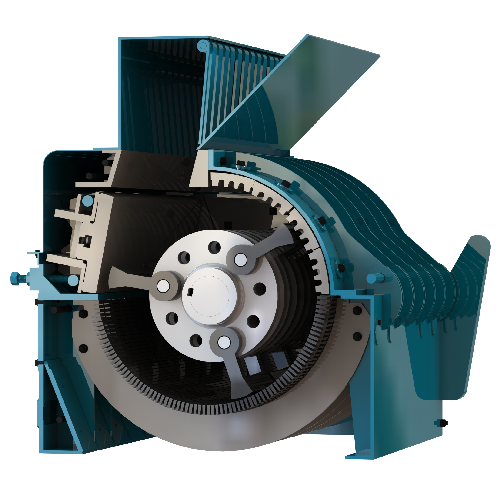

Lanway have been making Hammermills for over half a century and some of the earliest machines are still in operation today.

Our Hammermills are extremely robust, yet compact and very efficient.

Great Flexibility. Incredible Hammermill Design.

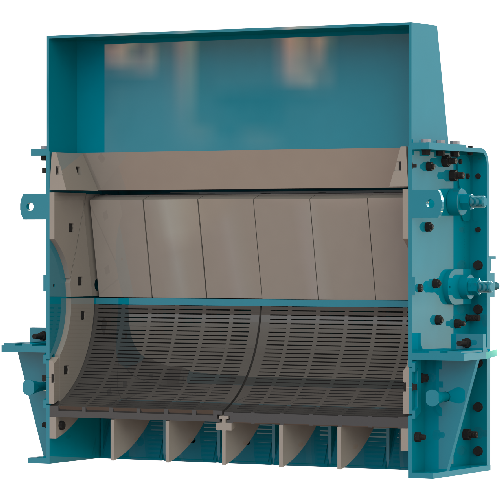

By changing the size of the grid bar panels, adjusting the distance from the ‘anvil block’ to the hammer path and varying the rotational speeds, the desired result can be achieved in one pass, be it fine ground agricultural limestone or 40mm crush & run (Clause 804). Should a different product be required the machine can be adjusted accordingly.

Outstanding Service. All Spares Stocked.

Should you require factory personnel to service or fit replacement parts to your Lanway Hammermill you will be dealing with people with in-depth knowledge of our products and who possibly helped to build your Hammermill in the first place.

We can supply (off the shelf) all spare parts for every Hammermill we have ever built. It’s as simple as that. Need we say more?